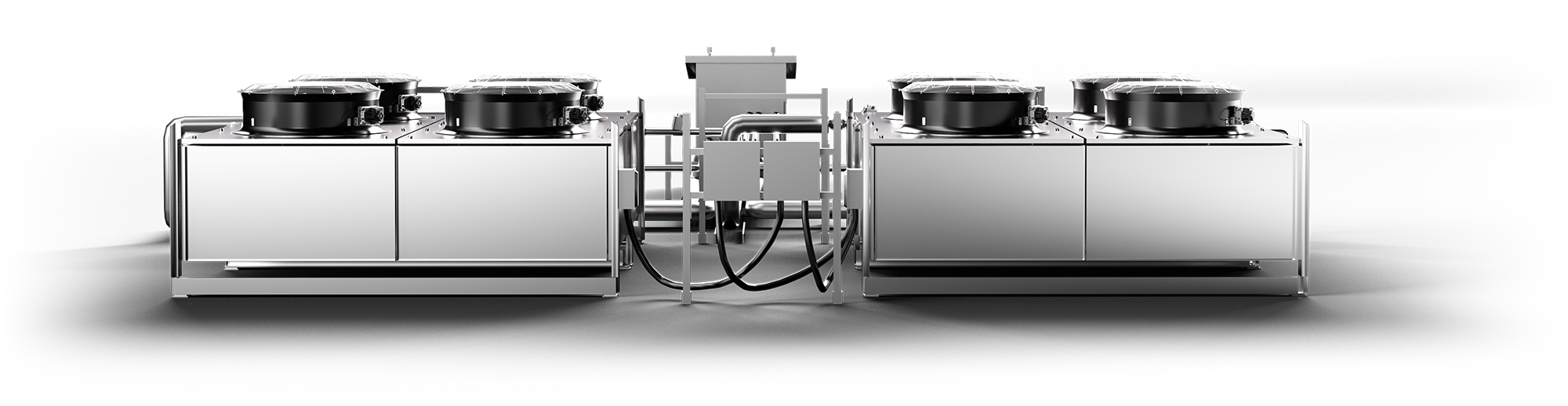

Given that cooling towers come in all shapes and sizes, finding the perfect fan can be a bit like finding the right shoe size. Enter our L-series axial fans.

Our large, variable-speed fans are custom-built to handle corrosive environments, ensuring durability and efficiency. Plus, our tailored designs mean you save on energy costs and skip the hassle of installing multiple smaller fans.