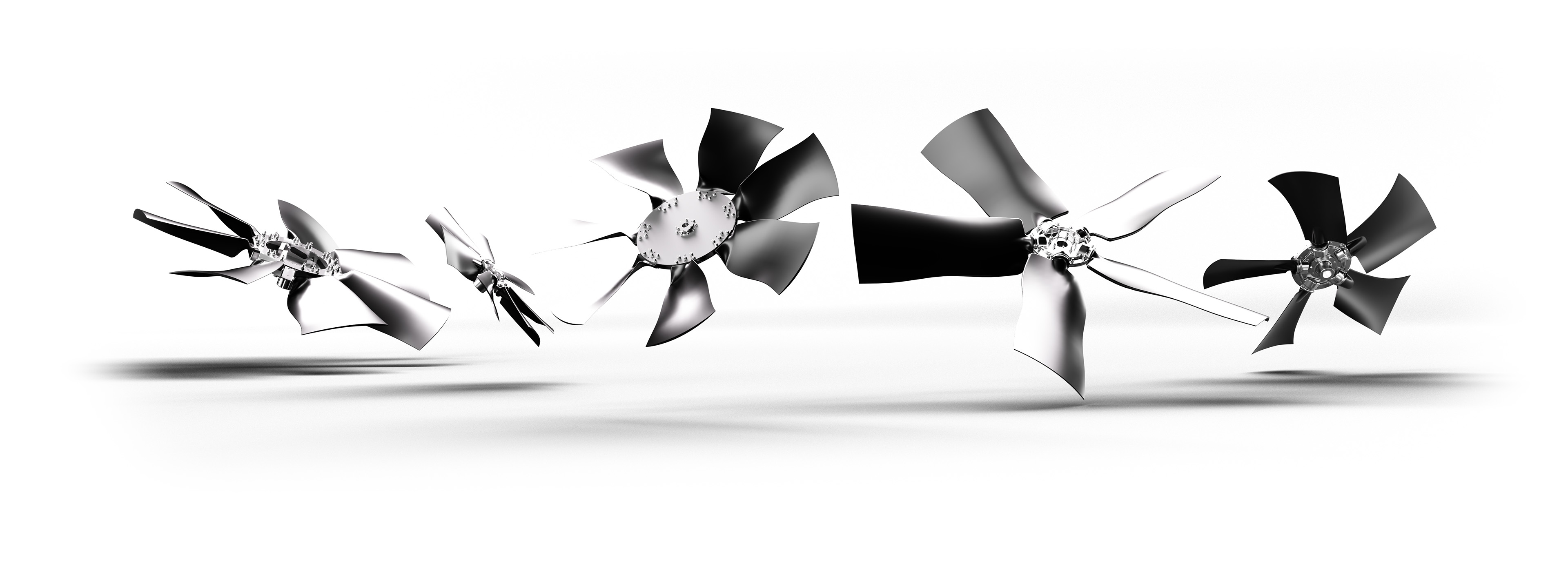

Adding a viscous clutch to an impeller brings speed modulation, reduced fuel consumption and lower noise.

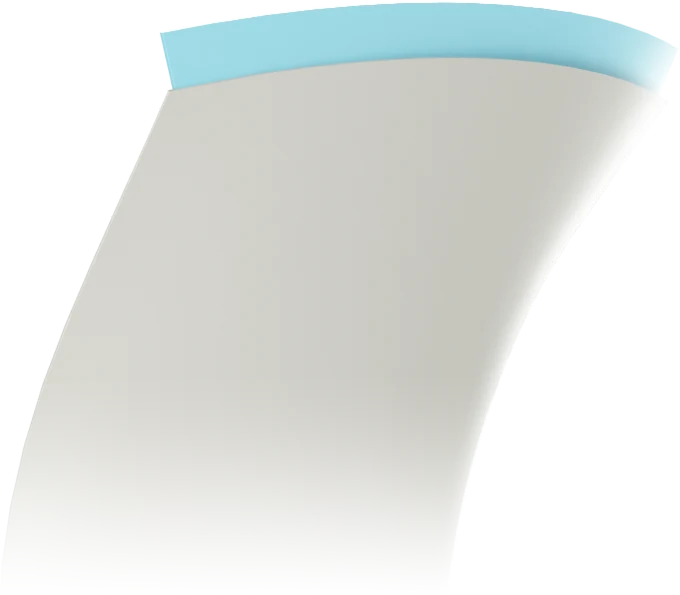

Flexible fan blade extensions reduce noise and improve efficiency by minimizing the tip clearance.

Winglets reduce blade tip vortexes and minimize fan noise.